EXPLORING ESSENTIALS

The quintessential components of high-temperature insulated wires encompass the conductor, insulation, protective braid, jacketing, and shielding. It’s not necessary for every construction to have all these elements. More straightforward constructions might merely need a conductor and insulation. However, when rigorous service conditions at high temperatures are anticipated, a more elaborate construction could be necessary. Each of these elements should be deliberated considered.

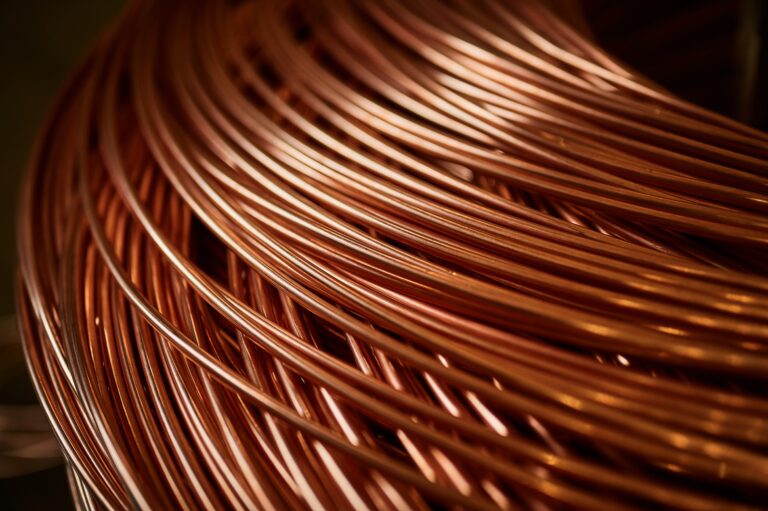

Conductor

Key factors in selecting the appropriate conductor include the type of conductor material, the diameter of the conductor, and the stranding. The anticipated operating temperature is a primary concern, as different conductor materials have varying degrees of heat resistance. Subsequently, the ability of the conductor to transmit current without exceeding the temperature limits of both the conductor and insulation should be considered. For more details on ampacity, please consult the tables provided by NEMA or NEC for relevant information.

Conductor | Maximum Temperature Rating, °C | Bare Copper

| 200

|

|---|---|

Tinned Copper

| 200

|

Nickel-Plated Copper (2%)

| 250 |

Nickel-Coated Copper (27%)

| 550

|

Silver-Plated Copper

| 200 |

Nickel-Plated Iron

| 250 |

Nickel | Nickel |

Insulation/Jacket

Primary insulation serves the critical function of harnessing and directing voltage. Materials chosen for this primary insulation role, such as thermoplastics, synthetic rubbers, and mica, exhibit excellent dielectric capabilities along with heat resistance. In instances of more demanding applications, it’s worthwhile to assess if secondary insulation may be necessary to guard against potential harm such as cuts, tears, or other forms of damage. Since primary insulation is typically chosen with its dielectric strength in mind, the selection process might involve balancing trade-offs between this factor and physical properties.

Our extensive range of insulation options at Casmo ensures that we can meet diverse customer requirements. Our offerings include various types of insulation materials:

Insulation Types | Materials | Fire Resistance | Chemical Resistance | UV Resistance | Durability | Flexibility | PFA | -100°C to 260°C

| Excellent

| Excellent

| Good

| Excellent

| Good |

|---|---|---|---|---|---|---|

Foamed PFA

| -100°C to 260°C

| Excellent

| Excellent | Good | Excellent | Good |

TFE

| -70°C to 260°C

| Excellent

| Excellent

| Excellent

| Fair

| Fair |

PTFE | -60°C to 200°C

| Excellent

| Excellent

| Excellent

| Good

| Good

|

Foamed FEP

| -70°C to 200°C

| Excellent

| Excellent

| Excellent

| Good

| Fair

|

FEP

| -80°C to 200°C

| Excellent

| Excellent

| Excellent

| Good

| Fair

|

ETFE | -70°C to 150°C

| Excellent

| Excellent

| Good

| Good

| Good

|

ETFE

| -100°C to 150°C

| Good

| Excellent

| Excellent

| Excellent

| Excellent

|

Silicone

| -80°C to 180°C

| Good

| Fair

| Excellent

| Fair

| Excellent

|

XLPO | -40°C to 105°C

| Excellent

| Good

| Excellent

| Good

| Fair

|

TPE | -50°C to 105°C

| Excellent

| Fair

| Excellent

| Good

| Good

|

PVC | -20°C to 105°C

| Good

| Good

| Excellent

| Good

| Good

|

XLPE | -40°C to 105°C

| Good

| Excellent

| Good

| Good

| Good

|

PP | -40°C to 105°C

| Poor

| Excellent

| Excellent

| Fair

| Poor

|

PUR/PU/TPU

| -55°C to 80°C

| Poor

| Excellent

| Good

| Excellent

| Excellent

|

PE | -60°C to 80°C

| Poor

| Fair

| Excellent

| Good

| Good

|

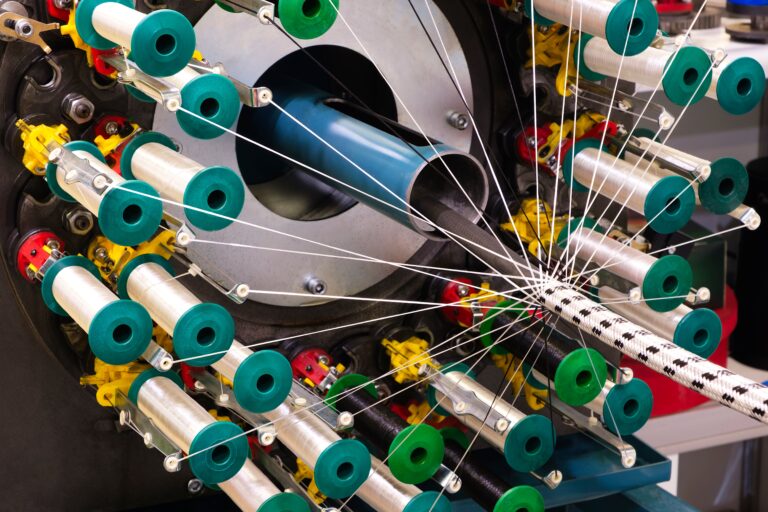

Braiding

Fiber glass is widely used in braided outer covers for limited mechanical protection. Glass braid almost always is saturated with an appropriate high-temperature finish to prevent fraying or moisture penetration and to improve fiber bonding.

Shielding

Metal shielding, applied as a corrugated or flat tape or as a woven braid used to protect insulation from severe operating conditions. Additionally, it prevents power-generated interference from escaping to the surrounding environment. Metallic shielding also is commonly used in low-voltage communications wiring to protect signal integrity.