Hazardous Substances Compliance Testing

Cable Noise Profile Evaluation

Design and Manufacturing Plan Visualization

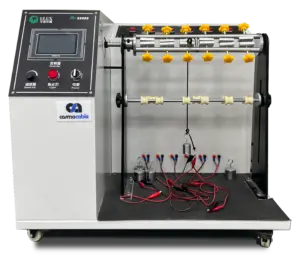

Dynamic Condition Endurance Testing

Cable Strength and Flexibility Testing

Cable Sheathing Quality Testing

Heat Flow Properties Testing

Microscopic Cable Structure Analysis

Flame and High-Temperature Resistance Testing

Long-term Durability Testing

Maximum Tensile Strength and Strain Capacity Testing

Environmental Condition Performance Testing

Cable Robustness Testing under Drastic Environmental Conditions

Extreme Heat Resistance Testing

High Voltage Resistance Testing

High Current and Temperature Rise Performance Testing ……